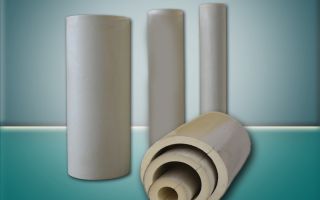

Pipe insulation has a suitable thermal property that is affordable to use in different industries due to energy. The product is produced with high pressure injection machine or the cutting of large blocks in different densities and thicknesses.

Application:

Pipe insulation is mostly used in pipelines and equipment with low temperatures.

Features:

Flame retardant

Flame retardant

Self-Extinguishing (PIR – b1, PUR – b2)

Self-Extinguishing (PIR – b1, PUR – b2)

Close the cell and without fiber

Close the cell and without fiber

High compressive resistance & durability

High compressive resistance & durability

Easy installation

Easy installation

Technical Data

|

Properties

|

Unit

|

Type IV

PIR & PUR

|

Type II

PIR & PUR

|

Type III

PIR & PUR

|

Type V

PIR & PUR

|

Type VI

PIR & PUR

|

| Service Temperature |

C°

|

-183 to 149

|

-183 to 149

|

-183 to 149

|

-183 to 149

|

-183 to 149

|

|

Min Density

|

Kg/m3

|

32

|

40

|

48

|

60

|

96

|

MaxThermal Conductivity

At 24 C°

|

(w/m.k)

|

0.027

|

0.027

|

0.029

|

0.029

|

0.032

|

|

Min Compressive Strength

|

Kpa

±10%

|

150

|

240

|

310

|

550

|

862

|

|

Max Water Absorption by Volume

|

%

±10%

|

2

|

1

|

1

|

1

|

0.8

|

|

Max Water Vapor Permeability

|

(ng/Pa-s-m)

±10%

|

5.8

|

5.1

|

4.4

|

3.7

|

2.9

|

|

Hot Surface Performance

|

|

At 150 C°

|

At 150 C°

|

At 150 C°

|

At 150 C°

|

At 150 C°

|

![]() Flame retardant

Flame retardant ![]() Self-Extinguishing (PIR – b1, PUR – b2)

Self-Extinguishing (PIR – b1, PUR – b2)![]() Close the cell and without fiber

Close the cell and without fiber![]() High compressive resistance & durability

High compressive resistance & durability![]() Easy installation

Easy installation