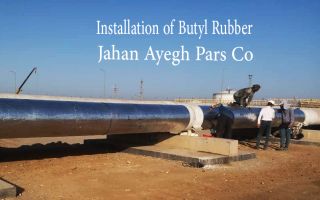

Aluminum Butyl laminate is a kind of vapor barrier jacketing used to protect equipment against water and vapor which must be installed with the use of torch or any industrial dryer for the temperature up to 30 °C. The jacketing consists of a high tack butyl adhesive covered with aluminum foil that laminated to one silicon film to provide high level of protection (puncture and tear resistance).

The product is convenience for coating rigid insulation such as Cellular/Foam Glass and PIR&PUR which can be replaced to vapor barrier mastic & aluminum jacketing.

Application:

- • Sealing & waterproofing of Hot & Cold Insulation & Pipelines

- • All kinds of waterproofing & sealing treatment under the sun such as civil roofing, steel structure

Features:

- • Resistance against sunlight and UV

- • Stable chemical properties

- • Corrosion & water resistance

- • Excellent adhesion

- • Environment friendly

- • Non – Toxic

- • Fire Resistance (Class B2 – DIN 4102)

Precautions for Installation:

- • All surfaces should be dry and free of dust, oil and grease.

- • Choose proper size of butyl sealing tape

Delivery and Storage:

- • Jacketing should not be stored where it may come in contact with hydrocarbon solvents such as petroleum spirit and diesel oil or other organic solvents.

- • Jacketing should be handled and stored in a manner as not to damage the material and its packaging. For best results, rolls should be stored vertically.

- • Jacketing should be protected from inclement weather by storing indoors, where material will not exceed 80 °C for extended periods. Jobsite storage in well ventilated containers, or covered on pallets is suitable for temporary periods.

- • Store products in a heated building during cold weather or prior to cold weather application.

- • Store away from sparks or flames