What is Foam Glass?

Foam/Cellular glass insulation is a rigid, closed-cell insulation material made from recycled glass, offering excellent resistance to moisture, chemicals, and compressive loads

Foam Glass is one of the most recent insulating systems in the documentation and technical specification of oil & gas refineries, petrochemical, and power plants as a priority of hot & cold insulation systems.

Foam glass is a convenient alternative to Rock Wool or PIR & PUR, according to its advantages such as high Compressive & Flexural Strength, Water & Vapor Barrier, use on the floor of tanks and underground pipelines, Extreme Chemical Resistance, Non-Destruction of Environment & Ozone Layer. It's a kind of cold insulation which the temperature ranges from -268 to + 427 ℃ and is produced exclusively of glass, with some other additives in its composition acc. to ASTM C552 in basic block form. Blocks are fabricated into a wide range of shapes, thicknesses, densities, and sizes to satisfy industrial insulation requirements.

Cellular Glass is the best insulation to be used in solar panels (solar panel roof and facade system) because of its great compressive and non-combustibility.

![]() No deterioration of thermal conductivity

No deterioration of thermal conductivity![]() Vapor and water-resistant

Vapor and water-resistant![]() Dimensional stability

Dimensional stability![]() Chemically neutral

Chemically neutral![]() High compressive strength

High compressive strength![]() Resistant to insects and rodents

Resistant to insects and rodents

Due to a lack of cellular glass production in past years and some matters like: Exit Exchange, Higher price compared with other kinds of insulation, Impossibility of carrying out quality control process on imported products, Sanction and impossibility of supplying from authoritative sources, thus fewer projects in domestic oil & gas refineries and petrochemical has been used the insulation.

Although there isn’t any scale for corrosion resistance of PIR, concerning the nature of the glass as well as lack of chemical material and additives in foam glass structure, which is without a binder therefor is highly resistant to corrosion in various environments.

It should be noted that foam glass is the only insulation used for both hot and cold applications with different thicknesses, that some spec is as follows:

![]() Spec of insulation for hot & cold application, TOTAL CO.

Spec of insulation for hot & cold application, TOTAL CO.![]() Spec of cold insulation, phases 12& 19 of South Pars, Petropars Co

Spec of cold insulation, phases 12& 19 of South Pars, Petropars Co![]() Spec of cold insulation, phases 15& 16 of South Pars, Aria Naft Co.

Spec of cold insulation, phases 15& 16 of South Pars, Aria Naft Co.![]() Spec of cold insulation, phases 13,22 & 24 of South Pars, Iranian Petro Paydar & Petrosina Petrochemical Industries Co.

Spec of cold insulation, phases 13,22 & 24 of South Pars, Iranian Petro Paydar & Petrosina Petrochemical Industries Co.![]() Spec of cold insulation, Bueshehr Petrochemical

Spec of cold insulation, Bueshehr Petrochemical![]() Spec of cold & hot insulation, Ilam Petrochemical

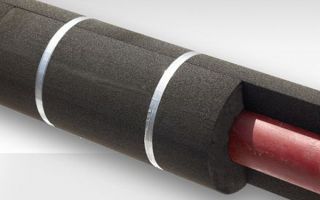

Spec of cold & hot insulation, Ilam Petrochemical![]() Based on Spec of insulation at the phases of South Pars to use foam glass in LPG lines & the lines out of the phases that include one layer of PIR and one layer of Foam Glass.

Based on Spec of insulation at the phases of South Pars to use foam glass in LPG lines & the lines out of the phases that include one layer of PIR and one layer of Foam Glass.

Foam Glass properties in COMPARISON with PIR

![]() Compressive strength of Foam Glass is 1.5 to 2.6 times more than PIR

Compressive strength of Foam Glass is 1.5 to 2.6 times more than PIR![]() The water barrier of Foam Glass is 4 to 10 times higher than that of PIR

The water barrier of Foam Glass is 4 to 10 times higher than that of PIR![]() The vapor barrier of Foam Glass is 600 times more than that of PIR

The vapor barrier of Foam Glass is 600 times more than that of PIR![]() The Flame Spread Index of PIR is about 5 times more than that of Foam Glass

The Flame Spread Index of PIR is about 5 times more than that of Foam Glass

Comparison between PIR & Foam Glass

Due to the nature of the glass as well as the lack of chemical material and additives in foam glass for fire resistance parameter is non-combustibility.

According to the abovementioned matters and considering the advantages of foam glass to PIR & Mineral Wool (considering all kinds of insulation at Jahan Ayegh Pars Co.) and due to the huge investment made by Jahan Ayegh Pars Company as a first domestic and Middle East manufacturer, it's possible to replace Foam Glass with a competitive price with PIR.

Some of THE Foam Glass projects implemented by Jahan Ayegh Pars

![]() Mapna Group

Mapna Group![]() Ilam Petrochemical

Ilam Petrochemical![]() Sepahan Oil Co

Sepahan Oil Co![]() Takhte Jamshid Petrochemical

Takhte Jamshid Petrochemical![]() Pars Petrochemical

Pars Petrochemical![]() Amir Kabir Petrochemical

Amir Kabir Petrochemical![]() Persian Gulf Petrochemical

Persian Gulf Petrochemical

Frequently Asked Questions

Is foam glass resistant to water absorption?

Yes, it has a fully closed-cell structure.