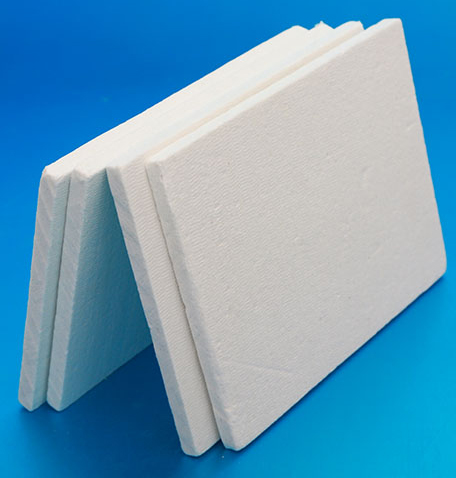

Ceramic fiber board of Jahan Ayegh Pars Company is manufactured and designed for thermal applications requiring high demands on rigidity. The thermal insulation properties and abrasion resistance of ceramic fiber board have been further improved due to the higher density. Ceramic fiber board is a vacuum-formed product that resists higher gas velocities than ceramic fiber blanket.

The product is designed to resist erosion, vibration, mechanical stress, and installation and can be produced in different shapes according to customer order.

Applications:

![]() Boiler and water heater linings for combustion areas

Boiler and water heater linings for combustion areas

![]() Ceramic kiln and industrial furnace linings

Ceramic kiln and industrial furnace linings![]() Backup insulation for bricks and other refractories

Backup insulation for bricks and other refractories![]() Wherever high-temperature insulation is required

Wherever high-temperature insulation is required![]() Refractory lining

Refractory lining![]() Hot face lining

Hot face lining![]() Gaskets and seals

Gaskets and seals![]() High-temp baffles and muffles

High-temp baffles and muffles![]() Flue and duct linings

Flue and duct linings![]() Infrared and electrical element support

Infrared and electrical element support![]() Launder and trough linings for nonferrous molten metals

Launder and trough linings for nonferrous molten metals![]() Launder covers over molten metals or molten salt

Launder covers over molten metals or molten salt![]() Parting material to provide protection against molten metal splash

Parting material to provide protection against molten metal splash![]() Expansion joint boards

Expansion joint boards

Features:

![]() Low thermal conductivity

Low thermal conductivity ![]() Low heat storage, stability at high temperatures

Low heat storage, stability at high temperatures![]() Excellent resistance to thermal shock, chemical attack, water, and oil damage

Excellent resistance to thermal shock, chemical attack, water, and oil damage![]() Reduced refractory heat-up and cool-down time

Reduced refractory heat-up and cool-down time![]() High rigidity and light weight for ease of handling, cutting, drilling, sawing, and machining

High rigidity and light weight for ease of handling, cutting, drilling, sawing, and machining![]() Excellent acoustic insulation

Excellent acoustic insulation![]() Easy Installation

Easy Installation