Foam Glass Board | Lightweight, Durable, and Sustainable Insulation

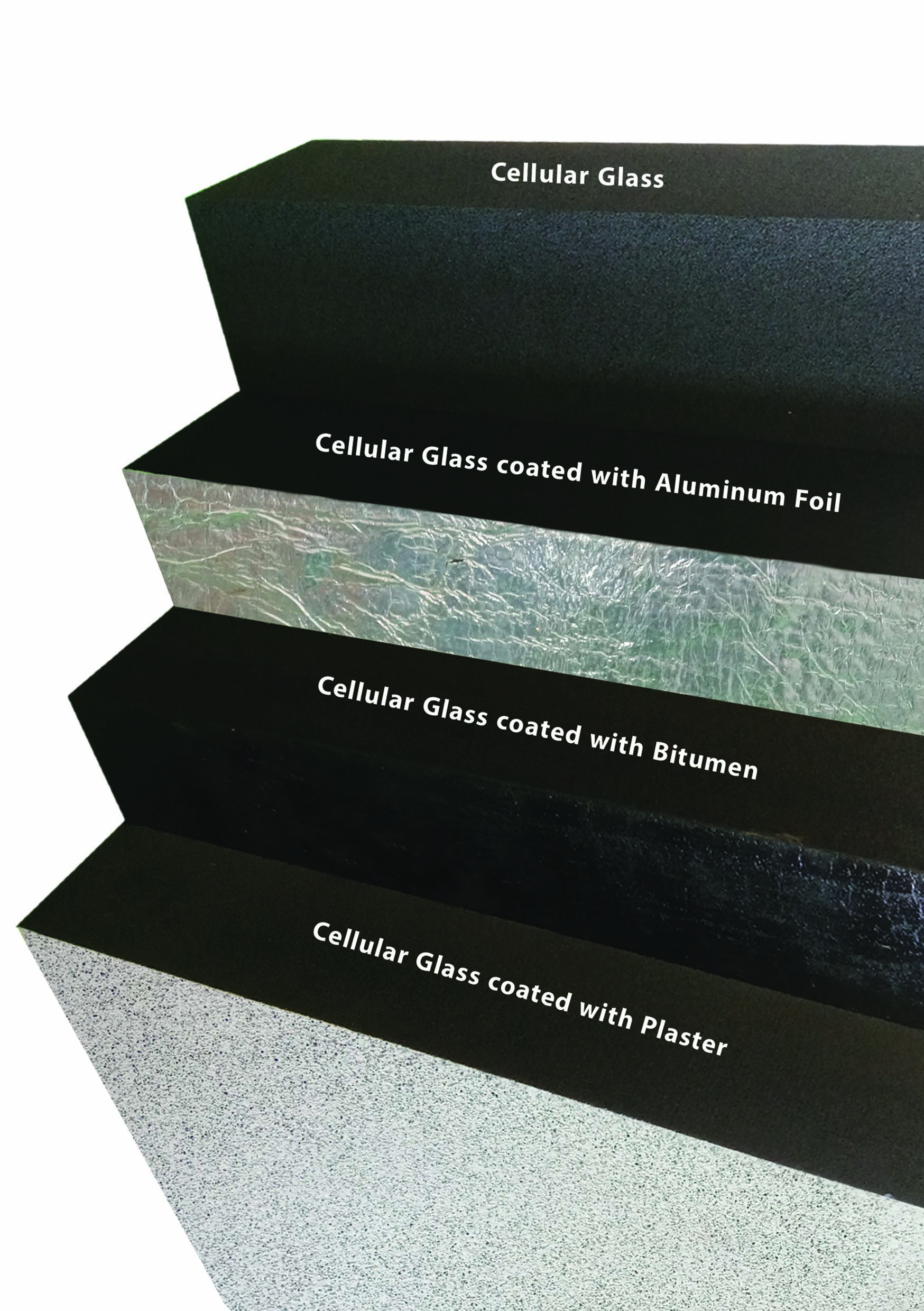

Foam glass board is an advanced insulation material produced from recycled glass. Thanks to its closed-cell structure, it offers zero water absorption, high compressive strength, and outstanding long-term durability. This product is widely used as a thermal and cryogenic insulation in industries such as oil & gas, petrochemical, power plants, construction, and cold storage facilities.

Foam Glass Board Insulation of this company is prefabricated in board and block shapes in a wide range of densities and sizes according to customer order. This close cell insulation is convenient for board surfaces such as walls and doors, also tanks at low temperature, cooling systems, and different industries such as refinery oil, power plants, and buildings.

Applications:

![]() Petrochemical, oil and gas refinery, power plants, and the building industry

Petrochemical, oil and gas refinery, power plants, and the building industry![]() Barrel, sphere, tank in low temperature

Barrel, sphere, tank in low temperature ![]() Cooling system

Cooling system![]() Heat Exchanger

Heat Exchanger![]() Pressure Vessels

Pressure Vessels![]() Wall & door

Wall & door

Features:

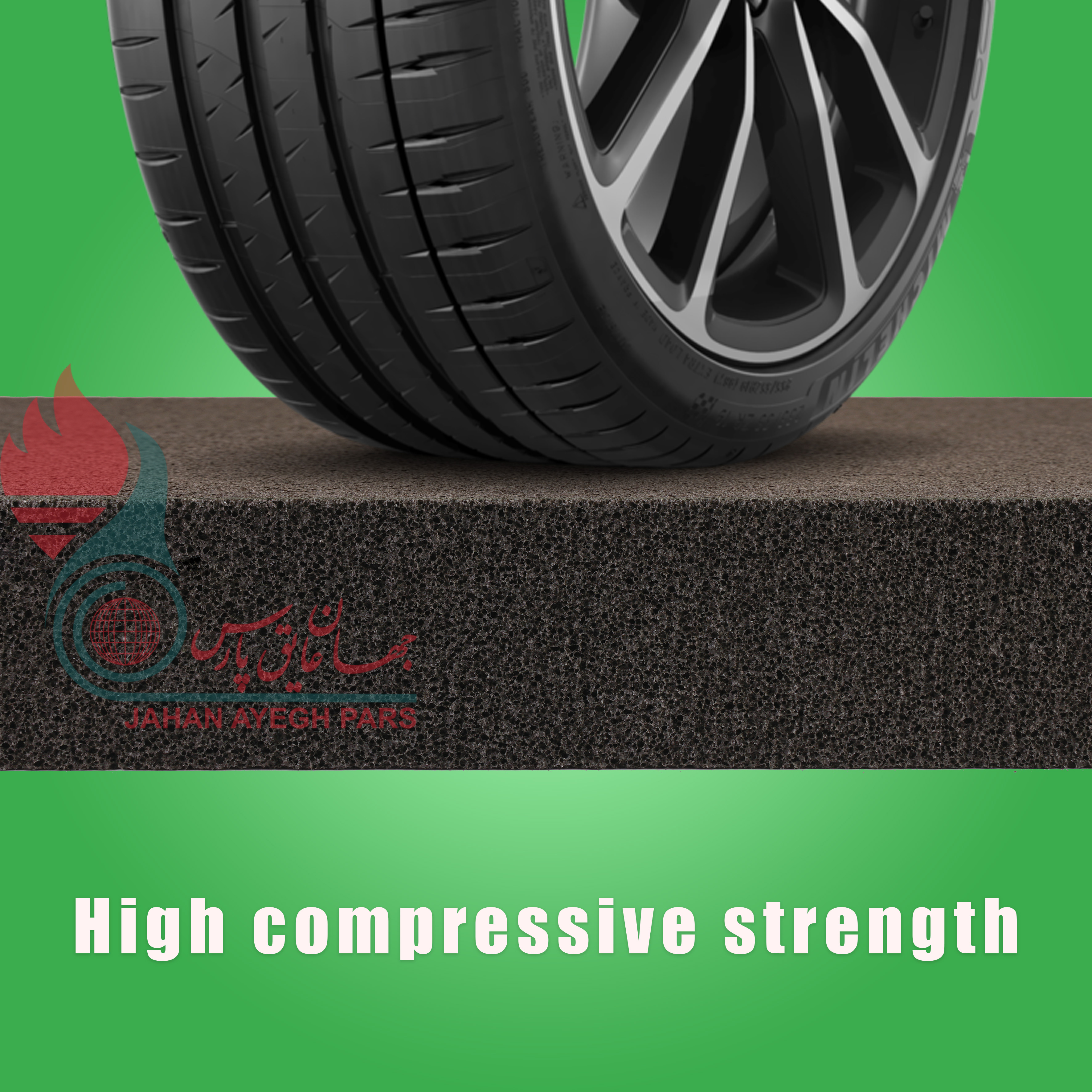

![]() Supreme compressive, tensile, and flexural strength

Supreme compressive, tensile, and flexural strength

![]() Incombustible

Incombustible

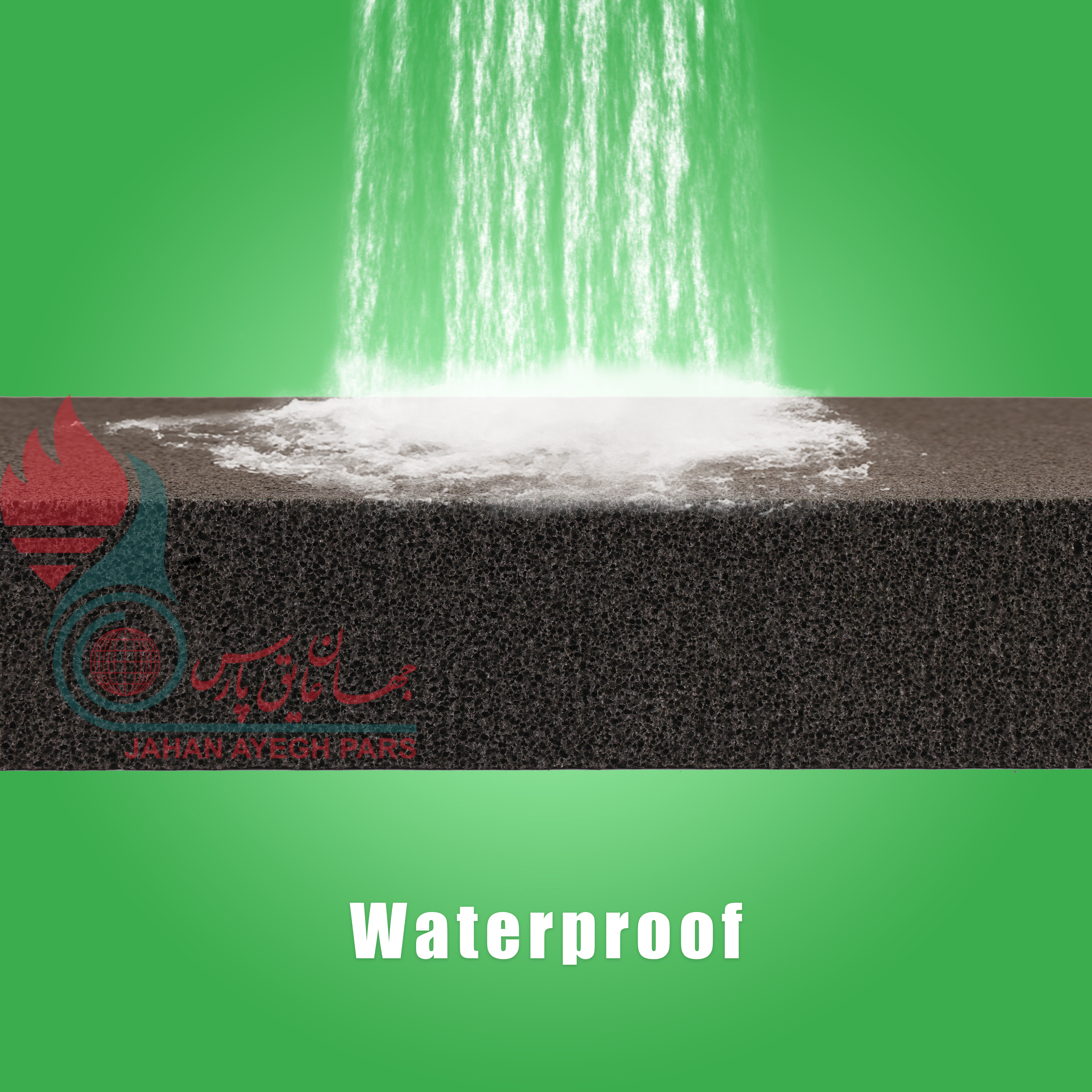

![]() Water and vapor barrier

Water and vapor barrier![]() Excellent thermal shot resistance

Excellent thermal shot resistance![]() Good sound absorption

Good sound absorption ![]() Excellent thermal stability

Excellent thermal stability![]() Light weight

Light weight ![]() Chemical resistance

Chemical resistance![]() Use for insulating hot and cold applications

Use for insulating hot and cold applications

Foam Glass Board VS. Rock Wool Panel in the Building and Construction Industry:

- 1- Both types are widely used in industrial, residential, and commercial buildings and constructions to reduce energy consumption.

- 2- The temperature service of Mineral Wool is -18 to 649 °C, and it is -268 to 427 °C for Cellular Glass.

- 3- Cellular Glass has extremely high compressive strength (Up to 827 KPA), and Mineral Wool is 48 KPA at maximum.

- 4- Mineral Wool is accounted as Hot Insulation, while Cellular Glass is known as both Hot and Cold Insulation; this is one of the major factors in cold regions.

- 5- Cellular Glass has a much longer lifespan than Mineral Wool.

- 6- Cellular Glass is Eco-Friendly, while Mineral Wool has a harmful environmental effect.

- 7- Water Absorption of Cellular Glass is a maximum of 0.5% volume and 2% for Mineral Wool.

- 8- Cellular Glass is completely resistant to animals and insects.

- 9- Cellular Glass is completely non-combustible.

- 10- Surface Burning Characteristics of both are as follows:

Mineral/Rock Wool Panel Cellular Glass Board

Flame Spread Index: MAX 25 Flame Spread Index: MAX 5

Smoke Developer Index, 50 Smoke Developer Index, 0