Installation Procedure of Cellular Glass/PIR & PUR Insulation Pipe

Preliminary Conditions:

-

The surface to be insulated should be clean and free from all traces of grease, rust, dust, and any foreign matter. Cleaning, such as sandblasting and priming of surfaces to be insulated, while recommended, is not part of this specification.

The surface to be insulated should be clean and free from all traces of grease, rust, dust, and any foreign matter. Cleaning, such as sandblasting and priming of surfaces to be insulated, while recommended, is not part of this specification. - If priming is specified, the primer must be thoroughly dry prior to the application of any insulation materials. The primer should also be compatible with any accessory materials.

The specifying engineer or owner shall, at their option, designate a rust inhibitor or corrosion-resistant paint to be applied before applying any insulation. The application of such paint or coating is not a requirement of this specification.

The specifying engineer or owner shall, at their option, designate a rust inhibitor or corrosion-resistant paint to be applied before applying any insulation. The application of such paint or coating is not a requirement of this specification. Any surface imperfection must be cleaned with a wire brush and then coated with a new layer of anti-corrosion paint or other suitable product. The surface must be moisture-free before the insulation is applied, and the product application must follow the anti-corrosion product manufacturer’s guidelines.

Any surface imperfection must be cleaned with a wire brush and then coated with a new layer of anti-corrosion paint or other suitable product. The surface must be moisture-free before the insulation is applied, and the product application must follow the anti-corrosion product manufacturer’s guidelines.- When an adhesive is used, the compatibility between the anticorrosion paint and the adhesive must be verified before applying the insulation.

Anti-abrasive coating is only to be applied if the piping is subjected to frequent and significant thermal movements or vibrations. The anti-abrasive coating must be applied to the inner side of the CELLULAR GLASS elements that will be in contact with the metal pipe or equipment.

Anti-abrasive coating is only to be applied if the piping is subjected to frequent and significant thermal movements or vibrations. The anti-abrasive coating must be applied to the inner side of the CELLULAR GLASS elements that will be in contact with the metal pipe or equipment.

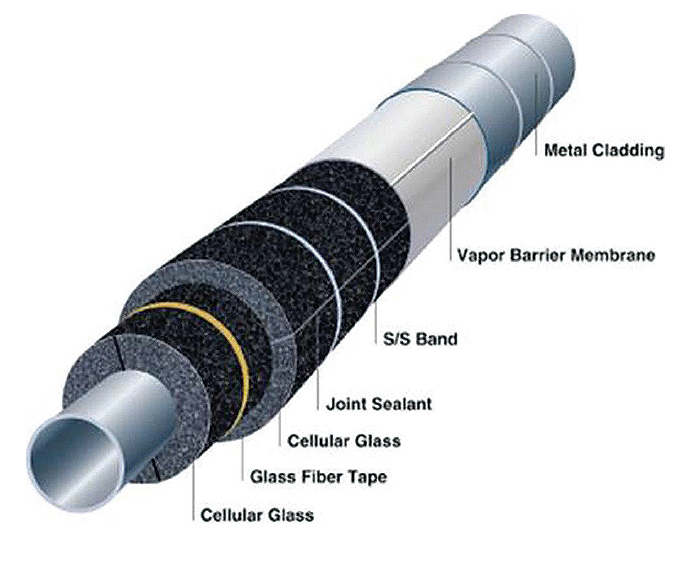

Procedure:

- Apply Joint Sealant 81-84: Place the sealant between the two semi-pipe sections to ensure a tight and secure fit.

- Fix with Filament Tape: Use filament tape to hold the semi-pipes in position.

- Coat with Vapor Barrier Mastic (Layer 1): Apply a layer of Vapor Barrier Mastic (60-90) to the surface for moisture protection.

- Add Fiber Glass Mesh: Place the fiber glass mesh over the first layer of mastic to reinforce the insulation.

- Coat with Vapor Barrier Mastic (Layer 2): Apply a second layer of Vapor Barrier Mastic (60-90) over the fiberglass mesh.

- Cladding Installation: Use Aluminum Jacketing or GRP as cladding material. Refer to the total specification (SPEC) for detailed cladding requirements.

- Secure with Sheet Metal Screws: Fix the cladding with sheet metal screws for a stable and durable installation.

- Seal with Silicone Mastic: Apply silicone mastic to seal any gaps and ensure weatherproofing.

Notes:

- In some specifications, Foam Seal 3045 is used longitudinally between the semi-pipes for enhanced sealing.

By following these steps, the insulation system will provide optimal thermal and moisture protection for the piping system.